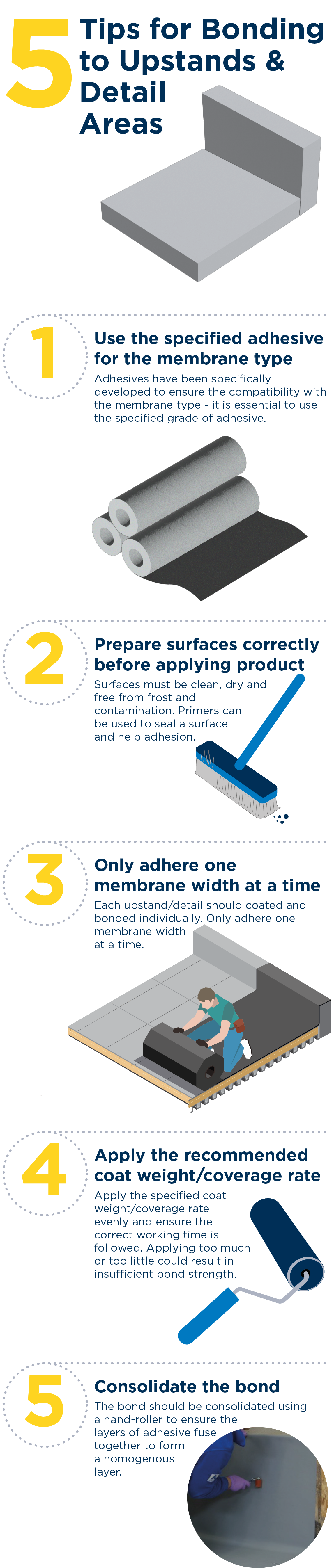

5 Tips for Bonding to Upstands & Detail Areas

Published: 23 September 2022

Updated: 07 October 2022

Securing membranes to upstands and detail areas can be the most difficult and time-consuming part of a roofing membrane installation – here Darrell Tibbins, Director of Technical, offers his top-tips to get maximum benefit from your adhesives.

Adhesives offer numerous benefits when securing membranes to roofs. They provide an even distribution of stress over the entire surface to ensure strong weatherproof bonds. Adhesives further help to promote the aesthetics of the roof, resulting in a clean and smooth finish.

Great care and attention should be used when waterproofing the detail areas of a roof, including the upstands, roof edges and junctions. Securing to detail areas is often the most difficult part of a roofing membrane installation as it involves bonding to vertical surfaces, often around apertures. It is more time-consuming compared with bonding field areas because it requires cutting and shaping the membrane.

Detailing adhesives are usually solvent-based contact adhesives, which are available as brush and spray grades. The adhesives have high initial strength and high-tack to produce an immediate bond between the membrane and the detail, preventing the membrane from lifting away.

1. USE THE SPECIFIED ADHESIVE FOR THE MEMBRANE TYPE

Adhesives have been specifically developed to ensure the compatibility with the membrane type. Single-ply membranes tend to fall into three main polymer types (EPDM, TPO and PVC) – each type has specific properties that affect how it can be adhered.

It is essential to use the specified grade of adhesive to ensure the correct level of adhesion and to meet the warranty of the waterproofing system. Adhesives are tested to a high standard by system manufacturers. Not using the specified adhesive risks the warranty being invalid, as well as giving unknown performance.

2. PREPARE SURFACES CORRECTLY BEFORE APPLYING PRODUCT

Surfaces must be clean, dry and free from frost and contamination. Adhesives will stick to anything they are laid on. If there is any contamination, such as moss, this will affect the bond and the integrity of the whole system will be compromised.

Different substrates and applications will present different problems; however, primers can be used to seal a surface and help adhesion. Primers come in a variety of different forms, the type needed will depend on the substrate and the type of adhesive or coating being applied.

3. ONLY ADHERE ONE MEMBRANE WIDTH AT A TIME

It is advised that each upstand/detail is coated and bonded individually to ensure the best results.

As bonding membranes to vertical surfaces can be time-consuming, only adhere one membrane width at a time. This will ensure that the detail work can be completed within the working time of the adhesive.

4. APPLY THE RECOMMENDED COAT WEIGHT/COVERAGE RATE

Always apply the specified coat weight/coverage rate evenly and ensure the correct working time is followed. This will allow for full bonding strength of the membrane. Applying too much or too little could result in insufficient strength to meet wind uplift and bond strength requirements. It could also diminish the aesthetics of the roof and increase project time and costs.

With solvent-based contact adhesives, once applied the solvents evaporate leaving a solid behind. The adhesive layer must be given time to allow the solvents to evaporate to prevent entrapment in the bond line. Applying too much adhesive may mean there is not enough time for the solvents to evaporate. This will reduce bond strength and can result in blisters or bubbles forming in the applied membranes.

Applying too little adhesive can reduce the open-times of solvent-based contact adhesives. You may not give yourself enough working time to position your material as it may start to dry too quickly. If working times are exceeded the two layers will not contact correctly resulting in lower bond strengths.

5. CONSOLIDATE THE BOND

It is important that a bond is consolidated correctly using a hand-roller to ensure the layers of adhesive fuse together to form a homogenous layer. This is the only way to ensure the two adhesives layers are in full contact. This is particularly important for roofing upstands and detail areas as it is more difficult to apply pressure to a vertical surface than on field areas. Rubbing the bonded surface with a hand will not form the correct bond, a hand-roller must be used.

Failure to consolidate the bond line correctly will result in a “tack bond” where the two layers of adhesive have touched to form a bond but have not fused correctly. This results in a weak bond, which will be prone to delamination, especially if exposed to direct sunlight.

Following the advice in this article will ensure you get maximum benefit from your adhesive when bonding upstands and detail areas.

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.