Polyurethane Liquid-Applied Membranes – Summer Tips

Published: 20 June 2023

Updated: 20 June 2023

The warmer temperatures expected throughout summer can affect the application of LAM systems. Here we offer our advice on how to get the most out of these systems during summer months.

It is easy to see why liquid-applied membranes (LAMs) are one of the fastest growing sectors of the construction industry. LAM systems are becoming an increasingly popular choice for flat roofing projects due to their versatility, durability, and reliability.

The warmer temperatures expected throughout summer can affect the application of LAM systems. Here, Darrell Tibbins, Director of Technical at Apollo Roofing, offers his advice on how to get the most out of these systems during summer months.

Polyurethane (PU) LAM Systems

PU liquid-applied membranes are generally cold-applied single-component roofing systems that cure to form a completely seamless and joint-free waterproof coating. They provide a hard-wearing and long-lasting waterproofing solution, even around complex details.

The systems are moisture-triggered, reacting with moisture in the air to cure once applied. They are largely multi-layer systems, consisting of a base-coat, an embedded glass fibre mat layer to reinforce the coating, and one or more top-coat layers. Systems can have a lifespan of 25+ years (dependant on number of coats). Once cured, it forms a tough coating that is weatherproof and tolerant to extreme temperatures (-30°C to 80°C), water and chemicals.

Single-component PU systems can help reduce project time, especially helpful in summer months when available working windows can be smaller. They do not require mixing and are simple to apply with a roller or brush, allowing for faster application.

While they are a great choice for new build projects because of the long guarantees that systems offer, LAMs also are ideal for repair or refurbishment projects. They are suitable for overlay and help extend the life of the roof without the cost of replacement. Systems are usually compatible with a wide range of roof substrates.

Summer Tips

Storage of Liquid-Applied Membranes

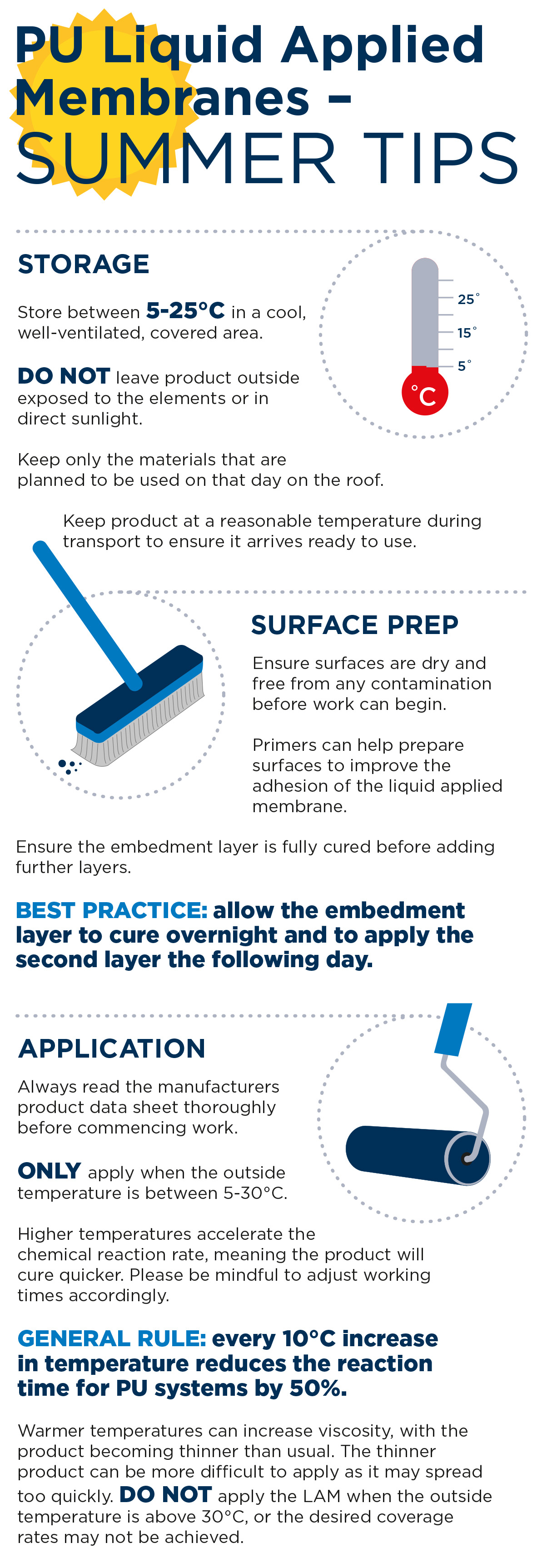

It is essential to store PU products appropriately during warmer weather. Products should be stored between 5-25°C in a cool, well-ventilated and covered area. Do not leave the products outside exposed to the elements or in direct sunlight. If products are stored on the roof, they should be stored on insulation rather than directly on the roof deck, which can get very hot. Keep only the materials that are planned to be used on that day on the roof. Keeping product at a reasonable temperature during transport is equally as important.

Following this will ensure your products are ready to use and will produce expected coverage rates, even on warmer summer days.

Liquid-Applied Membrane Surface Preparation

With rain still expected over summer months, products should only be applied in dry conditions. Substrates need to be prepared appropriately, ensuring they are dry and free from any contamination before work can begin.

Ensure the embedment layer is fully cured before adding further layers. It is best practice to allow the layer to cure overnight and to apply the second layer the following day.

Primers can also help prepare surfaces to improve the adhesion of the liquid applied membrane. Using the appropriate primer is vital to maximise the longevity of the roof and to comply with tested data. When applying LAMs, different substrates and applications will present different complexities. Primers come in a variety of forms and are often substrate specific. Each LAM primer has been formulated for a specific application/substrate, from overlaying asphalt, RBM, metal and various single-ply membranes.

Application of Liquid-Applied Membranes

Working with all LAM systems can be more difficult in summer, regardless of technology. The products will behave differently in warmer weather, but still can be an excellent waterproofing solution if care is taken when installing. Always read the manufacturers product data sheet thoroughly before commencing work.

PU systems should only be applied when the outside temperature is between 5-30°C. However, please be aware that the outside air temperature will affect its cure-time – the amount of time for the product to achieve its full bond strength. Heat accelerates the chemical reaction rate, meaning the product will cure quicker. Please be mindful to adjust working times accordingly.

Most manufacturers quote information on data sheets at 20°C. As a general rule, every 10°C increase in temperature reduces the reaction time for PU systems by 50%.

In warmer temperatures, you will see a noticeable change in the flow of the liquid-applied membrane. The product’s viscosity can decrease, with the product becoming thinner than usual. The thinner product can be more difficult to apply as it may spread too quickly, impacting the application and expected coverage. Do not apply the LAM when the outside temperature is above 30°C, or the desired coverage rates may not be achieved.

PU LAM systems offer an effective solution for your waterproofing projects. Using the systems properly and following our summer advice will ensure you result in a durable finished waterproof coating all year round.

The below infographic summarises the key points:

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.