Canister Disposal Guide

Published: 02 August 2019

Updated: 07 September 2022

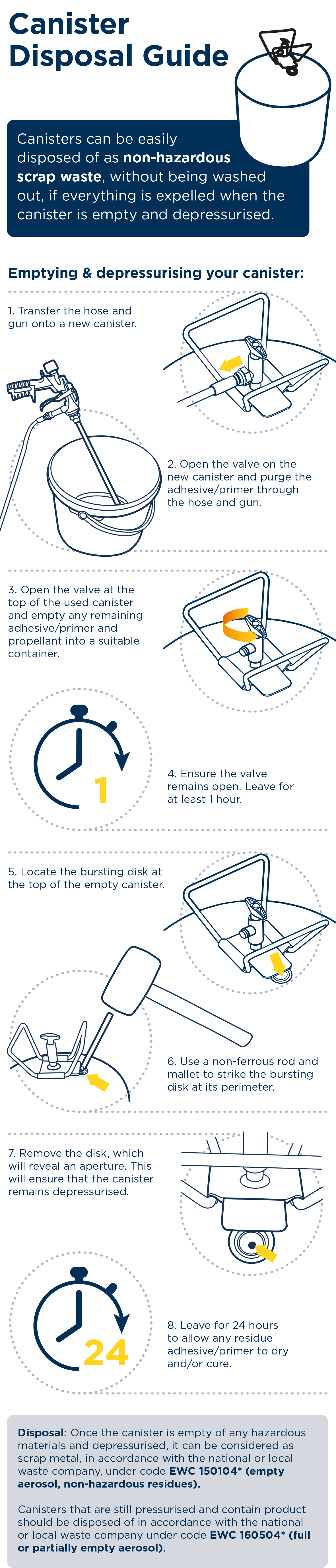

Here we explain the waste packaging rules, and how to safely depressurise and correctly dispose of your canisters after use.

A key benefit of using roofing adhesive and primer canisters is that they can be easily disposed of as non-hazardous scrap waste if everything is expelled when the canister is empty and depressurised.

Disposal Rules

The disposal of packaging can be a topic often raised by contractors, with many unsure of how to correctly dispose of their adhesive and primer containers after use. One of the main areas of confusion is classification – hazardous or non-hazardous? All waste must be classified in accordance with the Environmental Agency’s Technical Guidance (WM3), which covers all types of packaging, including everything from bottles and tins to canisters.

Standard Packaging Disposal

For standard packaging, including containers ranging from bottles through to tins and drums, to be classified as non-hazardous waste, it must be treated in such a way that all reasonable efforts have been made to remove any left-over contents from the packaging. Find out more information on standard packaging disposal here.

Canister Disposal

Canisters can be easily disposed of as non-hazardous scrap waste, without being washed out, if everything is expelled when the canister is empty and depressurised.

How to safely empty and depressurise your canister. The instructions are also available in the Canister Set Up & Maintenance Guide.

- Transfer the hose and gun onto a new canister.

- Open the valve on the new canister and purge the adhesive/primer through the hose and gun.

- Open the valve at the top of the used canister and empty any remaining adhesive/primer and propellant into a suitable container.

- Ensure the valve remains open. Leave for at least 1 hour.

- Locate the bursting disk at the top of the empty canister.

- Use a non-ferrous rod and mallet to strike the bursting disk at its perimeter.

- Remove the disk, which will reveal an aperture. This will ensure that the canister remains depressurised.

- Leave for 24 hours to allow any residue adhesive/primer to dry and/or cure.

Please ensure that your contractors are fully trained in this procedure. Personal Protective Equipment (PPE), including protective clothing, gloves and safety glasses, should always be worn. The procedure should also only be conducted outdoors or in a well-ventilated area. Always consult the Safety Data Sheet (SDS) first.

Disposal Codes

After the procedure has been followed, the canister will be empty of any hazardous materials and depressurised. Therefore, it can be considered scrap metal in accordance with the national or local waste company, under code EWC 150104* (empty aerosol, no hazardous residues). Waste companies like to see the canister punctured with the valve unscrewed to prove no gas or product is left in it.

Canisters that are still pressurised and contain adhesive/primer should be disposed of in accordance with the national or local waste company under code EWC 160504* (full or partially empty aerosol).

Canisters are therefore easy to dispose of, and being a bigger unit, there is also less industrial waste compared to tin products. The coverage of one canister of adhesive can be the equivalent of up to six 6L tins. Although the canisters cannot be reused, the metal is recycled rather than going to landfill – providing further environmental benefits.

For more advice regarding the disposal of canisters and other containers, please contact Apollo’s Compliance department.

Our infographic below summarises the article:

You may also be interested in

Canister Depressurising and Emptying Video

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.